GEOLOGY OF THE SURROUNDING AREA

The geology of the Stonehouse area is entirely of Carboniferous age: 360 million years to around 300 million years.

The oldest rocks in the area are Clyde Plateau Volcanics of Lower Carboniferous (Dinantian) age that outcrop to the west of Stonehouse and underlie a large part of Strathaven, as well as small parts of Stonehouse parish e.g. Crumhaugh farm.

Strathclyde Group (Dinantian):

Rocks of the Lawmuir Formation overlie the older Clyde Plateau volcanic; they consist of sandstones with siltstones, mudstones and minor limestones, ironstones and coals e.g. Stonehouse Under Limestone and Cot Castle Clayband Ironstone.

Clackmannan Group (Dinantian – Namurian):

Lower Limestone Formation; composed of cyclic sequences of sandstones, siltstones and mudstones with significant beds of marine limestone, a few thin coals and ironstone. The base of this unit is the Hurlet limestone which was extensively quarried around the area of the Limekilns. The Top Hosie limestones mark the top of this unit.

Limestone Coal Formation: consists of cyclic sequences of sandstones, mudstones and coals. The Crutherland coals are the local equivalent of the 9 Foot seam elsewhere in Lanarkshire.

Upper Limestone Formation: again, a cyclic sequence of sandstones and mudstones with important limestone beds and minor coals and ironstones. The Index limestone marks the base of this unit and locally the Plean No.2 limestone marks the top. Much of the rest of this unit was eroded prior to the deposition of the Passage Formation.

Passage Formation: mainly sandstones with fireclays, seatearths and minor coals.

Coal Measures (Westphalian):

Lower Coal Measures; consist of cyclic sequences of sandstones, mudstones and ironstones with many important coal seams that were worked in mines locally e.g Drumgray Coals and Kiltongue Coal.

Middle Coal Measures; similar sequence to the Lower, but coals locally less important.

Upper (Barren) Coal Measures; similar again to the above but few coals and much of the strata reddened.

Quaternary:

Dimlington Ice sheet covered the area from 28,000BP to 18,000BP. Many glaciated features, erosional and depositional, occur within Stonehouse area.

ECONOMIC GEOLOGY

1. COAL: Lower and Middle Coal Measures (Westphalian)

Limestone Coal Group (Namurian)

2. IRONSTONE: Coal Measures and Limestone Coal Group.

3. SANDSTONE: (also known as Dimension stone): Lower Coal Measures. e.g. Overwood Quarries

4. LIMESTONE: Lower Limestone Group – shales w/ ironstone ribs, limestones, a few thin coals. Main limestones: Hurlet, Blackhall and Hosies.

5. Upper Limestone Group – arenaceous character, thick shale beds, 4 – 8 limestones, a few thin coals. Main limestones: Index, Lyoncross, Orchard, Calmy and Pleans.

6. FIRECLAY: Mostly from Passage Group strata but also many inter seam seat earths and clays in Coal Measures.

7. OIL SHALE: The Lawmuir Formation (LWM) is the local equivalent of the Upper Oil-shale Group below the Hurlet Limestone.

COAL MINING IN SCOTLAND

During 12th/13th Centuries – coal was mined by monks of Holyrood, Newbattle, Dunfermline and Paisley Abbeys. Until the 16th Century coal mining was localised and used only primitive methods.

Pumping machinery was developed at the end of 16th Century which allowed working to greater depths in de-watered mines.

Steam power appeared in early 18th Century. James Watt’s steam engine revolutionised mining in Scotland by allowing better drainage and winding from deeper levels.

The expansion of the iron industry in the 19th Century led to a dramatic increase in coal demand. The rise in coal demand was also linked to improved transport/communications and general economic and social improvement.

Coal output in Scotland was around 40,000t/annum in 1550 which rose to around 500,000t/annum in 1700. Production peaked at 43 million t/annum at the start of WWI.

The Central Coalfield in Lanarkshire is the historical heartland of industrial Scotland where Coal Measures seams were worked to near exhaustion in shallow drift mines long ago and production of good quality coking coals from Limestone Coal Group (Namurian) seams never reached projected levels of production. The Central Coalfield suffered from high production costs and decreasing demand from a declining steel industry.

COAL MINING IN STONEHOUSE AREA

Canderrigg / Broomfield Mine Owner J Nimmo & Co

Canderside /Garibaldi ”

Coal Mines and Seams Worked in South Lanarkshire

Mine Name Mine Owner

OVERTON Coltness Iron Co

ASHGILL Merry & Cunninghame

FERNIEGAIR Archd. Russell

MERRYTON Cochrane & Brand

QUARTER Colin, Dunlop & Co

SKELLYTON Hamilton & MacCulloch

CANDERRIG / BROOMFIELD J. Nimmo & Co

CANDERIGG SHAFTS 4 AND 5 (NS 7876 7696; BROOMFIELD)

Although the principle mine buildings are located in Dalserf Parish adjacent to the Cander Moss SSSI, the shafts themselves are more closely associated with Stonehouse, evidence of which can still be seen today. Shaft/Mine Details: 3 shafts, No.4 shaft 62m, No.5 shaft 84m, and Draffan shaft 59m deep. In 1948, the mine was outputting 190 tons per day, 51,300 tons per annum. 267 employees.

Screening: 3 picking belts (moving conveyor belt onto which raw coal from the mine was spread out and manually picked over to remove debris and stones). Bash-tank type washer, by Inglis Engineers, Airdrie (coal preparation to separate coal from dirt whereby water is forced through coal using a plunger, perforated plate and tank). Canteen (pieces only), no baths or medical services. All electricity DC, generated at colliery. (Report dated 11-08-1948. RCAHMS 2006)

Mines 4 and 5 were owned by James Nimmo & Co. producing steam, house and gas coals. The sinking of these shafts just south of Broomfield farm commenced in 1902 and closed in 1954. It worked the same field as Canderrigg or Canderside 2 & 3 pits whch were to the south east of the canderside bridge.

The average workforce during this time (combined with shafts 6 and 7) was 379, with a peak workforce of 582 in 1947.

Shaft details: No.4 62m, No.5 84m and Draffan 59m. In 1948 these mines were producing 190 tons of coal per day, 51,300 tons per annum (267 employees). Screening: three picking belts. Bash-tank type washer, by Inglis Engineers, Airdrie. Canteen (piece only), with no baths or medical services.

CANDERIGG SHAFT 6 (NS7766 4679) AND 7 (NS 7749 4669)

Mines 6 and 7 were owned by James Nimmo & Co. producing steam, house and gas coals. The sinking of these shafts commenced in 1939 and closed in 1964. Shaft details: No.6 (NS 7766 4679) 168m dipping 1 in 6, No.7 (NS 7749 4669) 104m dipping at 1 in 2.24. In 1948, these mines were producing 300 tons of coal per day, 81,000 tons per annum (311 employees). No baths, canteen or medical services. DC electricity all generated at No.4 pit.

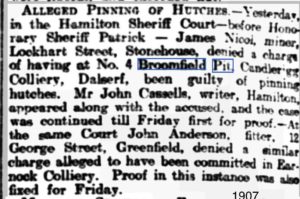

The seams were wet and narrow and roads were very low. Miners had to be careful to push the hutches with their hand flat on the hutch or their fingers could be caught on the roof.

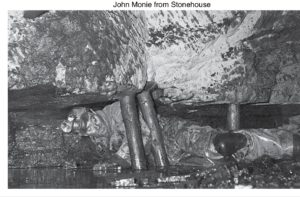

The picture below shows John Monie from Stonehouse working a section of Canderigg plus locos and picture of the pit.

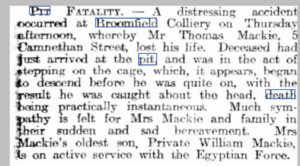

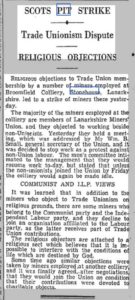

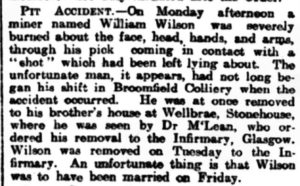

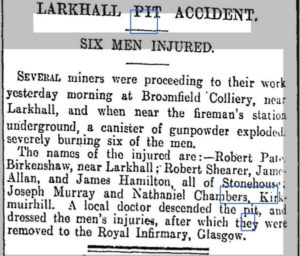

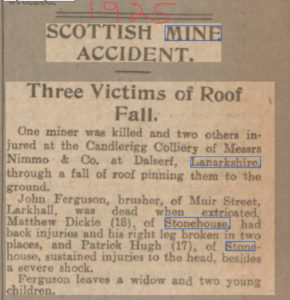

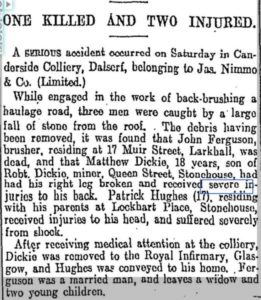

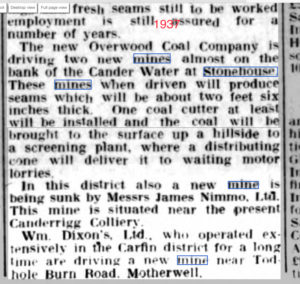

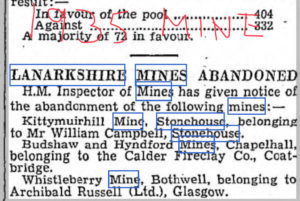

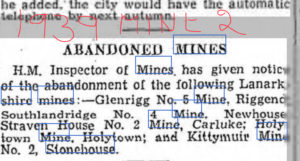

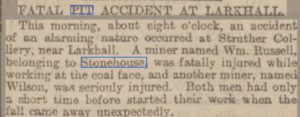

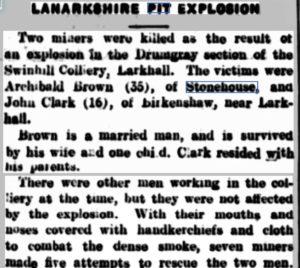

Work was dangerous and many accidents were recorded with the following newspaper cuttings confirming this.

CANDERSIDE / GARIBALDI

OVERWOOD – Stonehouse Overwood Coal Co.

THINACRES – Hamilton

“ “ “

KITTYMUIR NO. 2 – St’house W.G. Walker, Airdrie

STRUTHERHILL-LARKHALL

SUNNYSIDE – LARKHALL

SWINHILL- LARKHALL

WOODSIDE – DALSERF Wilson & Clyde Coal Co

Coal Seams of Lanarkshire (Hamilton District)

Westphalian

Upper (Barren) Coal Measures – only Barncluith coals. Chatelherault sandstone

Middle Coal Measures

Glasgow Upper

Ell Index

Glasgow Ell

Pyotshaw

GlasgowMain

Humph

Glasgow Splint

Airdrie Blackband

Lower Coal Measures

Airdrie Virtuewell

Ladygrange

Kiltongue

Upper Drumgrey

Middle Drumgrey

Lower Drumgrey

Shotts Gas =Craignethan Dross

Mill = Auchenheath Lime or Dross

Upper Ball =Lesmahagow Main Gas

Armadale Ball

Colinburgh

Namurian

Limestone Coal Group

Crutherland coals (House, Jaunt and Smithy) =nt to?Nine Foot

COAL MINING IN HAMILTON DISTRICT

Late 1830’s – coal mining began in the Quarter area from shallow drift mines. The Ferniegair pits opened around 1859.

By 1818 there were 40 pits located around Hamilton. Steam driven pumps and winding gear had been developed and by the 1890’s there were 257 collieries in the Lanarkshire coalfield and by 1920 the number of miners employed peaked at 62,000 with an annual output of around 18 million tons of coal.

The decline of coal mining in Lanarkshire was due in part to its early development and partly because of the thinner coal seams compared to those in the Lothians and Fife.

Miscellaneous

Avonbraes mine opened in 1940, was worked until 1969. It employed 26 men in 1958 and had an annual output of ~7,000 tons.

Beaton’s Lodge mine closed in 1961 – location?

Knowetop and Thinacre mines nationalised in 1947.

Canderrig mine closed in 1958

Coal Authority Data

2004 2005

South Lanarkshire opencast production 1.6Mt 1.3Mt

South Lanarkshire opencast coal Reserves 9.7Mt 8.4Mt

Reserves already permitted 1.2Mt 1.1Mt

IRONSTONE INDUSTRY

COT CASTLE IRON MINE

Newspaper article from 1864 writing about mine and railway

BLACKBAND IRONSTONE – ferruginous sedimentary rock associated with Coal Measures Fe carbonate (siderite) with up to 20% coal included which made it easy to smelt.

CLAYBAND IRONSTONE – fine grained red/grey/brown sedimentary rock of clay and siderite. It occurs as nodules, concretions and thin beds associated with coal seams in the Coal Measures.

Blackband ironstone was discovered in coal seams near Quarter in 1863-4 and by 1880 five furnaces were producing cast ingots. However, these deposits were largely exhausted by the late 1880’s.

Along the road between Glassford and Quarter, small mines were developed at Thinacre, Knowetop and Darngaber in the 1870’s possibly to replace the original mines closer to Quarter.

The Lawmuir Formation (LWM), (Upper Oil Shale Group), below the Lower Limestone Group formation (LLGF) contains the Stonehouse Under Limestone, the Cot Castle Ironstone and a number of thin coal seams.

MINING BOGIE (HUTCH) RESTORATION

Around 1995 a number of members from the heritage group retrieved a coal bogie (hutch) from the river Cander near overwood. The attached pictures show the bogie ion various states from its retrevial from the river to new wood for the axles. The repairs were carried out by Douglas Torrance and Robert Freel. The bogie was parked in the garden of 67 King street Stonehouse.

LIMESTONE INDUSTRY

Limestone Kilns (736 455): located below the road between Stonehouse and the Avon bridge were used to burn limestone quarried locally from the Hurlet Limestone to provide lime used to improve the quality of agricultural land.

FIRECLAY was worked mainly from Passage Formation strata, but there were also many seat earths and clays beneath coals in the Coal Measures. Clays were extensively quarried for tile making and field drains at the Tile works that were located at the bottom end of Union Street. The quarries were subsequently filled in with domestic watse brought in by rail from Glasgow and other urban areas. The site of the works is now a sports facility and the adjacent field that were once quarries are the site of the annual Agricultural Show.

James ‘paraffin’ Young patented the process in 1851 (the patent expired in 1864). The oil shale industry began in Bathgate in 1851 and lasted 100 years ending in 1962. The industry declined due to competition from petroleum discovered in Pennsylvania in 1859, but continued until 1962 due to a preferential tax scheme.

Cannel Coal/Torbanite/Oil Shale: In 1858 extensive oil shales of Carboniferous (Calciferous Sandstone Group) were discovered and led to an expansion of the industry in 1864 when Young’s patent expired. By 1874 production was around 500,000 barrels of oil/year. The industry peaked during WWI at around 2.1Mbarrels/year.

In the Stonehouse area, shale oil was won in small quantities from Cannel coals within the Coal Measures at the Ritchies (760 476) on the Avon downstream of the viaduct.

PIT DEATHS

Our members section has a name index of pit deaths of personnel linked to Stonehouse